Exclusive Interview | Helen Yang, Future Leaders 2026

A chemist by training, with a background in synthetic chemistry from Columbia University, Helen Yang is the founder of Clement Packaging, a San Francisco-headquartered company that offers a novel, compostable, plant-based packaging for consumer goods.

What inspired you to pursue a career In the packaging industry?

Helen Yang – I started my career as a cosmetic chemist, developing ’clean’ and sustainable formulas for beauty and personal care brands. However, I constantly faced a contradiction: no matter how sustainable the product inside was, we were packaging them in landfill-bound plastic. I was viscerally contributing to the plastic pollution problem with every product I launched.

I realized that focusing only on formulation wasn’t enough; quality products must include safe and sustainable packaging. As a chemist, when I couldn’t find a plant-based, toxin-free packaging material that was also shelf-stable and durable—I decided to invent my own and support the industry that I love.

What is one of the biggest challenges you’ve faced as a young leader in the packaging industry?

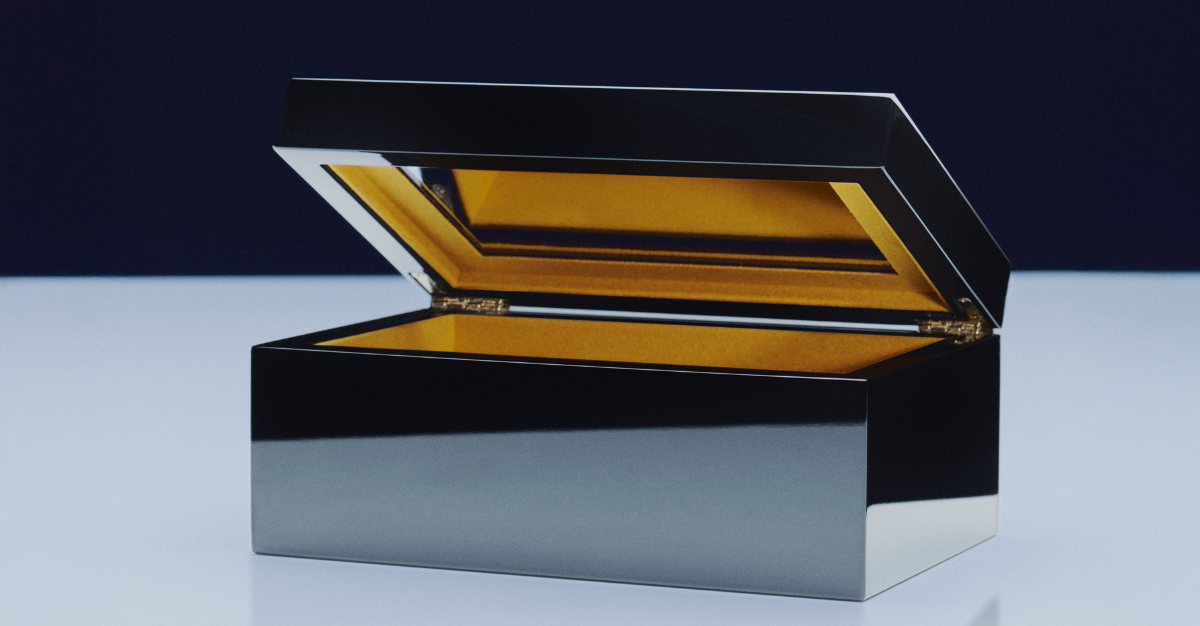

Helen Yang – Our biggest challenge was finding the balance between durability and compostability in a packaging material. Compostable alternatives for single-use plastics already exist, and those only need to weather a short period of time. In contrast, consumer goods with a multi-year shelf life need to survive varying temperatures and humidity, repeated opening and closing, and often even travel.

We spent 6 years formulating our material to be durable, lightweight, and compatible with complex liquid formulas without needing a plastic liner. As a young leader, it’s great to be bringing a fresh perspective and invention to the table.

If you could change one misconception about packaging, what would it be?

Helen Yang – Sustainability should entail not only reduction of carbon emissions, but also human safety and health. Often when we talk about sustainability in packaging, we focus on the lifecycle analysis: what raw materials are used? What is the footprint of shipping this packaging? How is this packaging disposed of at end of life? Of course this is all necessary and a packaging material is inherently not sustainable if it harms our planet, but it must come in tandem with safety and toxicology. It’s just as important to ask what additives are used in a packaging material, and whether it begets harmful microplastics. For example, a material that is renewably sourced but coated in PFAS may be a carbon win but is not sustainable for consumer goods in the long run.

This year marks 25 years of Paris Packaging Week.

What legacy do you hope this new generation of Future Leaders will leave behind for the next 25 years?

Helen Yang – This class of Future Leaders has an exciting mix of backgrounds from academia to industry, which I believe is crucial in leaving behind a legacy of action. We are excited to bring new technology from the R&D lab into the market, and the Future Leaders are embracing a new palette of materials and technologies to move beyond unrenewable fossil fuels.